Technological Parameters

|

Model |

DJ-2B |

|

Metering Mode |

Auger filling |

|

Package Weight |

50-5000g (by changing the auger attachment) |

|

Package Accuracy |

≤±0.3-1%(according to the packaging weight and product size) |

|

Packing Speed |

10-20times/min |

|

Power Supply |

380V/220V 50Hz/60Hz |

|

Hopper Volume |

50L |

|

Total Power |

2kW |

|

Total Weight |

300kg |

|

Overall Dimensions |

2400*900*2050mm |

|

Interface |

PLC control system, 5.7 inch touch screen |

|

Container Size |

Diameter 20-100mm; Height 50-200mm |

Feature

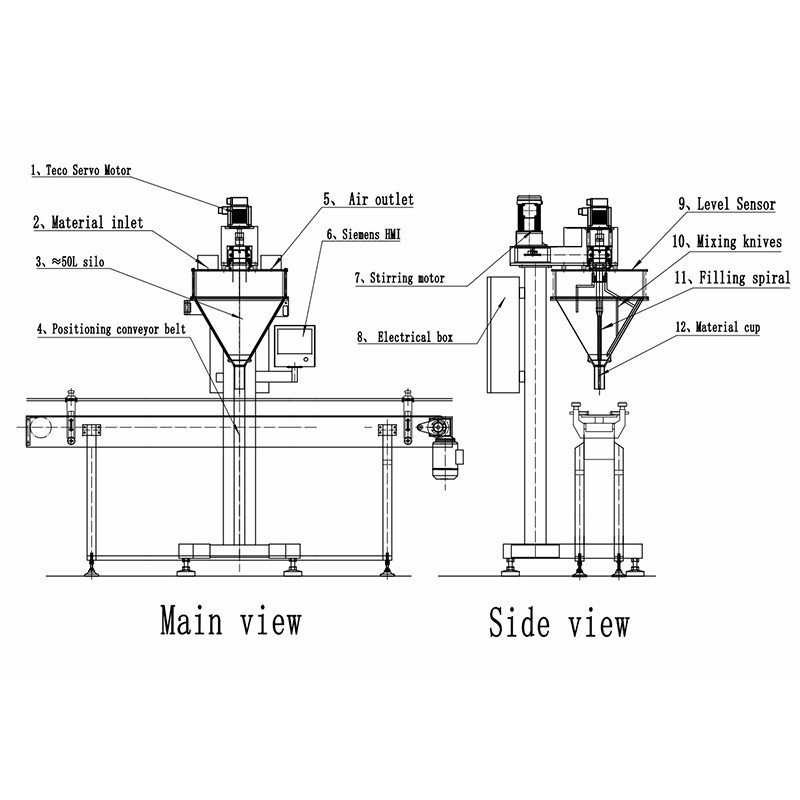

1. Wide Weight Range: The DJ-2B machine is capable of filling powders in the range of 50g to 5000g, catering to both small and large-scale packaging needs. The weight capacity can be easily adjusted by changing the auger attachment, providing flexibility for different packaging volumes and powder types.

2. Accurate Auger Filling System: The machine employs an auger filling system, driven by a servo motor, to ensure high precision in filling powders. The filling accuracy ranges from ±0.3% to ±1%, depending on the weight and type of product being filled. This feature guarantees consistent results and minimizes waste, making it ideal for bulk powder packaging.

3. Large Hopper Capacity: With a 50L side-opening hopper, this machine is designed for easy powder loading and cleaning. The side-opening feature simplifies maintenance and enhances operational efficiency by ensuring a smooth powder flow into the auger mechanism. A stirring device inside the hopper prevents clogging and ensures a consistent fill.

4. User-Friendly Interface: The PLC control system combined with a 5.7-inch touch screen provides intuitive operation, allowing users to easily adjust settings and monitor the filling process. The system is also customizable with Chinese or English language options, further improving user accessibility.

5. Efficient and Flexible Design: The DJ-2B is engineered with a compact and robust mechanical structure, ensuring ease of size part changes and cleaning. This makes the machine adaptable to a variety of powders, including fine powders and coarser materials, by simply switching accessories.

6. High-Speed Packaging: This machine boasts a packing speed of 10-20 cycles per minute, making it suitable for both medium and large-scale production. The high efficiency helps increase output while maintaining accuracy and quality in the filling process.

7. Durable and Reliable Components: The DJ-2B uses famous brand electrical components, ensuring stable and long-lasting performance. Additionally, the machine comes equipped with a vacuum cleaner to collect dust during operation, maintaining a clean working environment and minimizing powder wastage.

8. Versatile Container Sizes: The DJ-2B machine can handle a variety of container sizes with diameters ranging from 20mm to 100mm and heights between 50mm to 200mm. This makes it ideal for filling different types of bottles, jars, or barrels commonly used in various industries.

Hot Tags: automatic powder tin filling machine, China automatic powder tin filling machine manufacturers, suppliers, factory, semi automatic granule packing machine, Automatic Depalletizer, Double Head Rotary Powder Filling Machine, 25kg Bag Tunnel Sterilization Machine, Stainless Steel Platform, automatic powder bottle filling machine

![[[smallImgAlt]]](/uploads/43195/automatic-powder-tin-filling-machineb1689.jpg)